Having spent all my life in the Textile business, and with our firm being close to celebrating the centenary of its existence in Tanzania, I thought of noting my reminiscences of my years in the industry. The majority of readers may not find this their cup of tea, but considering that sharing is caring, here I go…

Going through my memory, I recalled some names of the fabrics popular in the era of the fifties and sixties:

Grey cloth (Marikan) Kaniki, Calico, Khaki Stockport (100% Cotton ex.England) Poplin, Basto (white sheeting) Silk, Linen, Satin, Chiffon, Georgette, Crep, Organdy, Organza, Twinkle Organza, Sersuccer, Slub, Spun, Rayon, Cepea, Crimplene, Jersey, Nylon, Perlon (aka Nylon 6), Voile, PK(pique knit), Airtex, Cheese cloth, Velvet, Muslin (malmal) and Flannel.

Not forgetting Damask, Brocade, Dobby and Taffeta which were produced under Jequard machines.

The name Damask originated from the city Damascus, where its technology was invented a long time ago, and later it travelled to China. Globally the name of the fabric came to be known as Damask.

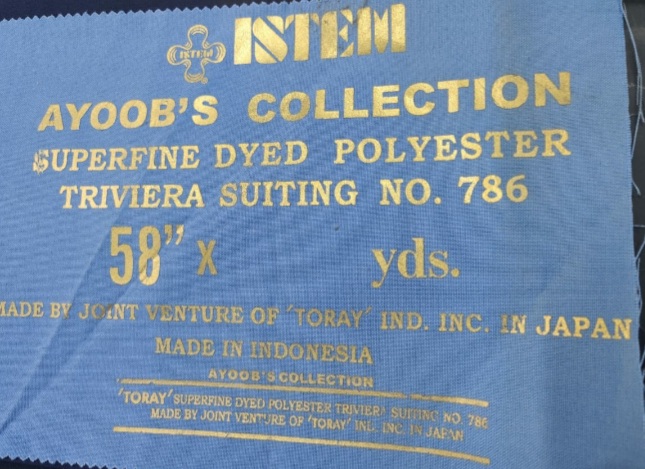

Primarily for Gents clothing were: Denim, Corduroy, Poplin cord, China cord, R 52, Woolen, Terylene (Ex England) Trevira (ex Germany), Tetrex, Teijin, (ex Japan), Marzotto (Ex Italy) Elena (East Europe) and Blazer.

The basic natural textile components are Cotton, Linen, Woolen, Silk, Jute and Hemp.

In the mid-fifties, Cepea in Manchester were manufacturing ladies and furnishing fabrics with 100% cotton. Ladies dress material with beautiful floral designs and attractive colour combinations made their product very popular.

I found Cotton to be the most “social” amongst its textile siblings! Cotton is a very versatile, friendly and co-operative fiber that can blend easily with its counterparts. Woolen was mostly mixed with Cotton and so was Silk or Satin.

On a lighter note- I compare cotton with potatoes. Potatoes in the food industry are the most popular and liked by the majority of food lovers. You can accommodate them in Biriyani, Pulao and also in all kinds of veg and non-veg curries to enhance the flavour. They can also be added within a simple roti to make aloo parotha! Likewise is Cotton in the textile industry.

Rayon was the first man-made fiber to be introduced in the textile market. The introduction of synthetics and the invention of Polyester and Viscose created a revolution in the textile industry. This change resulted in almost a disappearance of certain fabrics.

Most natural fibers now had their partners in the above synthetic fabrics. Eg: 100% Cotton drill Stockport became nonexistent; it was instead mixed with polyester to become American Khaki. Its most popular brand was made in Japan by Toray Industries, and branded # 8200.

Cotton was also blended with polyester to become Tetron.

The original fabrics started losing ground.

The demand for 100% Cotton fabric decreased mainly because of high cost and the fact that the cloth was vulnerable to creases. The fashion world was laying emphasis on smartly pressed garments. 100% Polyester had taken its place; it was also comparatively much cheaper.

The trend has changed now. The public has realized that polyester doesn’t breathe like cotton. These days wearing torn jeans is a fashion statement and so is wearing a cotton garment with creases. Psychologically a person feels he has upgraded his status!

Presently, China, India, Indonesia and Thailand with a couple of other Eastern countries are the main textile manufacturing nations. Their products are comparatively affordable because of cheap labour and the availability of raw materials in their own countries. Because of this, the West has lost its monopoly in the industry. The Cotton Industries of Manchester and Liverpool have died a natural death.

The most renowned and popular textile firm of Japan, The Toray Industries Ltd, established their factories in Indonesia and Malaysia.

Asides from developing nations, even the USA and European countries are now regular importers of fabrics made in China, Indonesia and Malaysia. Bangladesh is now the number one exporter of most designer brands’ ready-made garments stitched there with the fabrics imported from China.

Bangladesh reminds me of a forgotten piece of history which I am sharing here:

It was the 14th century when India started weaving a cloth called Malmal. It was unknown to the West at the time. The British later gave it the English name Muslin. Weavers from Dacca, now Dhaka (Bangladesh) were superior in their knowledge of the product which was so lightweight and soft, you could hold a full roll of 20+ metres of Malmal in a closed fist! It was given the special name of “Dhake ki Malmal.”

The colonisers started manufacturing Muslin in their English mills. They could not match the quality of the hand-woven original. This resulted in a ban in India and very sadly the weavers all had to pay a heavy price. Their thumbs were chopped off such that they could no longer weave, so eventually were out of their profession. A 1956 Bollywood movie was made depicting this piece of history.

South India had also invented a fabric which is now popular as Calico – named after the port Calicut in South India. Calico, a plain thicker and coarse woven fabric was also exported to Europe and other parts of the world. I believe India during that era had specialised in weaving different types of fabrics. Weavers in every state had their own cottage industries. Kashmiri and Banarasi weavers still manufacture quality shawls and saris respectively.

As the population increases so does demand. Thus many industries were established in the Eastern Hemisphere and each industry would also take individual orders to make fabrics as per the customer’s specifications (mainly in the construction and composition of the product). However, to mitigate cheating, many countries including Tanzania, have their own bureau of standards to control the quality. Products without due verification and certification from independent authentication bodies like SGS, Cotecna and few others, are not allowed to enter the country.

The buyer would have the prerogative to give the product its name.

In the last 50 years, the textile industry has witnessed considerable improvements and changes. Cotton and Linen are now Sanforized, a process of pre-shrinking by controlled progressive methods. Previously, the retailer would have to instruct the buyer to soak the fabric in water and dry it before stitching. (Imagine if they forgot!)

Technology has made fabrics like Linen and certain polyesters anti-static.

Most of the clothes now are Yarn Dyed. This is the process of dying the yarns first before spinning. This gives the assurance that the colour would not run. Yarn dyed fabrics cost more than otherwise.

Likewise Cotton also has its combed version, which is softer and crease resistant, but expensive.

My observation however is that the textile trade, in particular the retail sector, is dying- falling behind to make way for the ready-made garment business. The number of fabric shops have disappeared considerably in the developed West. The remaining shops cater mainly for those that consider dressing to be an art, or for those who favour buying fabrics of their own choice and prefer their garments made to measure. The days are probably not far when less developed countries will also follow suit.

A K A Bagha.

So much I didn’t know about the textile trade! Surprisingly interesting ☺️

What a scholarly writeup,bha!But then with your family’s century of innings,who else but you to enlighten us on this subject of sartorial excellence that separated the holloi polloi from the gentry!We grew up being told dress makes a gentleman,(sorry,Gandhiji!)

Your article mentioned R-52 (but not China cord),two of my late father’s fav dress materials.He was married in the first and wore the second to keep up with the Brit Joneses (and Smiths)who ruled over us in the then Tanganyika.Many years later,I had sourced both these from your shop,much to the surprise of your late father who had remarked that “No one asks for these nowadays”)and sold me suitlengths that were the last on the rolls.The late master tailor Mohamed Rafiq uncle did the honour of stitching new suits,as he had done the originals decades back.Not only time had passed,but tastes too.We were now with Nyerere’s collar less kimaus,borrowed from Kaunda’s more spiffy safari suits.

Fantastic!! Ayoob.

What a subject and how much wealth of knowledge you have accumulated.

I read and reread but still can’t grasp all since we knew of Khakhi kaptura and Gossage white shirts – our school uniform. Garam kapura was treat every Diwali I used to have stitched by our local Darji a Goan by name of Barreto. I still remember this name because he had two beautiful daughters by names of Lucy and Josephine. Thanks Ayoob. Let’s have some more on forgotten and fading memories.

Now that I’ve got started,try stopping me!Khaki stockport was the original uniform material of the 2nd rung officers and the police force during the Brit era.(The governor always wore white,remember,with a white pith helmet decorated with feathers from the chicken his missus must have cooked the previous night!NOW we can joke on the feathers.Then it would have been 7 years of “chakki pissing” as our Dharmendra would say much later.

The American khaki was sort of a bastardised version but more popular for school uniforms.Police officers wore their uniforms (called Jamba koti in Kiswahili (,maybe from Jumper coats)which had huge side pockets and many more pockets all over.Why they needed so many pockets is a mystery to this day.They didn’t take bribes necessiating storage place for illgotten wealth nor carried handcuffs and pistols and mace sprays and God knows what else like our Yankee cousins!Such was their aura of authority,highlighted with crisp starched khaki stockport uniforms pressed to a knife edge(pasi ya panga) by their laundry men.

A very informative and detailed description can only be given by a knowledgble man. Thank you for giving me the opportunity to read the brief history of Yarn.

The best Kaniki (black very crisp cloth)came from the David Sassoon mills of Baghdadi (Sephardic)jews of Mumbai,then still Bombay.Our native wearers had a handy test of excellence.The more rustling the material made,the better it was.Maybe it was an early warning system for a hubby being caught unawares!

But it was Marekani (the misnamed white/grey cloth that led the market.Originally brought by some enterprising but shortlived American sailor to Zanzibar(and hence the name)it was cut into two pieces,to be rejoined in the middle to make a wider shuka.And inevitably the buyer would ask for his “Zawadi”which was a safety pin or a clump of jaggery!

The best marekani came from Khatau mills or Morarjee mills of Bombay.So we exported our cotton from Tanganyika to India and imported finished textiles from there.

Beautiful article. You must have read so many books or other resources to get so much knowledge about textiles

What a brilliant piece of well researched work. Your work in fabric clothing has given you the opportunity to produce this piece of history which is unique in that no other retailers would have thought of compiling these historical facts.

I am sure this will be used as a reference for those researching into history of clothing.

Very well done and good luck.

The best Kaniki (black very crisp cloth)came from the David Sassoon mills of Baghdadi (Sephardic)jews of Mumbai,then still Bombay.Our native wearers had a handy test of excellence.The more rustling the material made,the better it was.Maybe it was an early warning system for a hubby being caught unawares!

But it was Marekani (the misnamed white/grey cloth that led the market.Originally brought by some enterprising but shortlived American sailor to Zanzibar(and hence the name)it was cut into two pieces,to be rejoined in the middle to make a wider shuka.And inevitably the buyer would ask for his “Zawadi”which was a safety pin or a clump of jaggery!

The best marekani came from Khatau mills or Morarjee mills of Bombay.So we exported our cotton from Tanganyika to India and imported finished textiles from there.

Basta,the whitest of the white textile (you almost needed sunglasses to stare at it in the sun)was reserved for shrouds (kafan) and of course,maybe for Jeetendra (the jumping jack!),not forgetting all Mumbai underworld dons,starting from Yusuf Patel to Haji Mastan Mirza.

So,the whitest of the whites finally clothed both,a saint and a sinner.”Do gaj kafanka tukda tera libas hoga” a childhood song promised.

There were tough times when simple essentials like toothpaste and Basta for kafan were in short supply in Tanzania.I remember our 20 kgs air travel weight allowance were taken up by stocks of ballpens,toilet soaps and 40 mtrs of Basta to Tanzania,to be donated for free “Sanda” to the dead of our village.Even normally strict Swahili Custom officers at Dar let us pass with smiles and a wave!